The quality of blood glucose test paper product automatic CCD detection equipment

Description:

1, machine vision CCD is done with machines instead of human eyes tomeasure and judge. machine vision systems by means of machine visionproducts will drain the target into image signals transmitted to thededicated image processing system, based on pixel distribution andbrightness, color, and other information into digital signals; imagingsystems for these various operations to extract the signal characteristicsof the target, According to distinguish the results of the control deviceto remove defective products and position measurement. entire system havequalified products database and the defect database, will all be CCD cameracapture products compared, separate the qualified and unqualified.

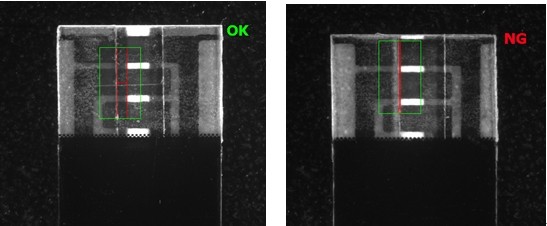

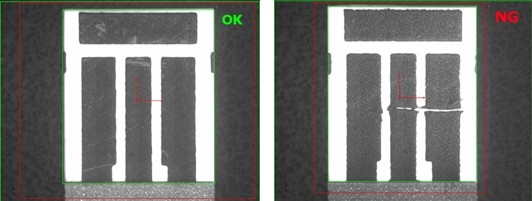

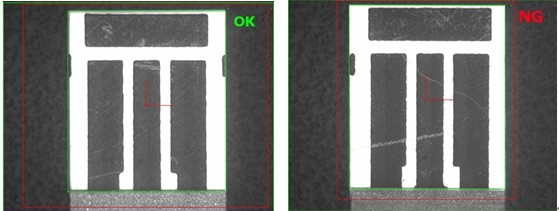

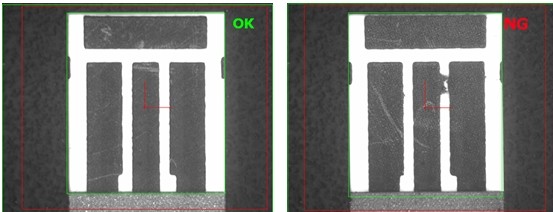

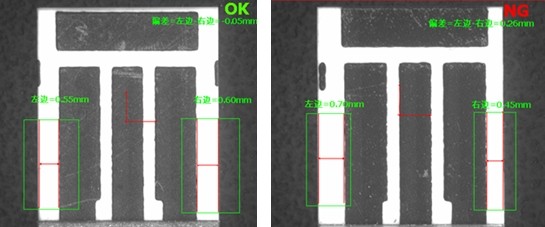

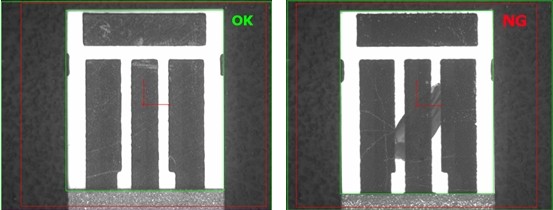

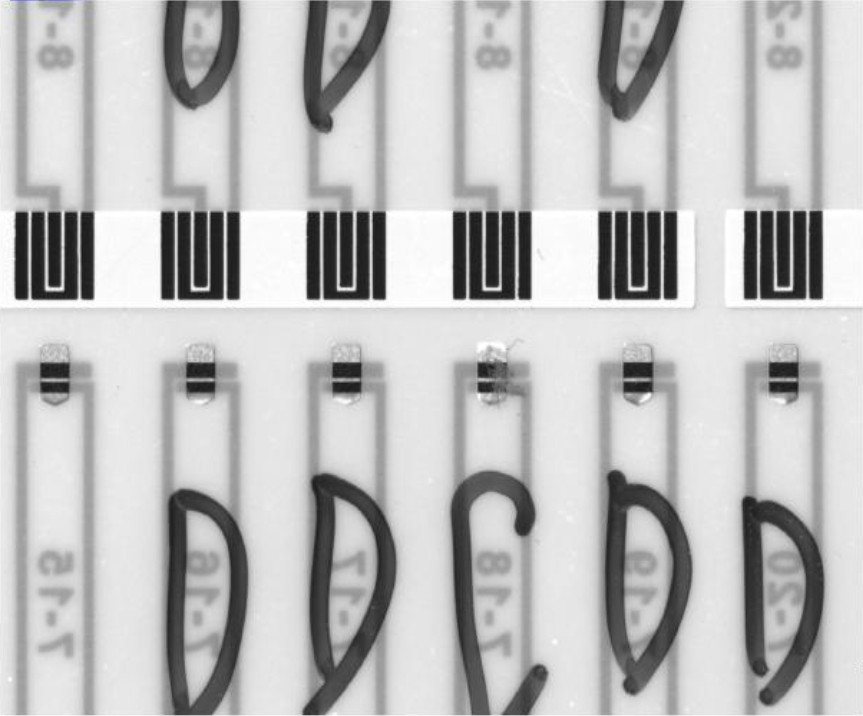

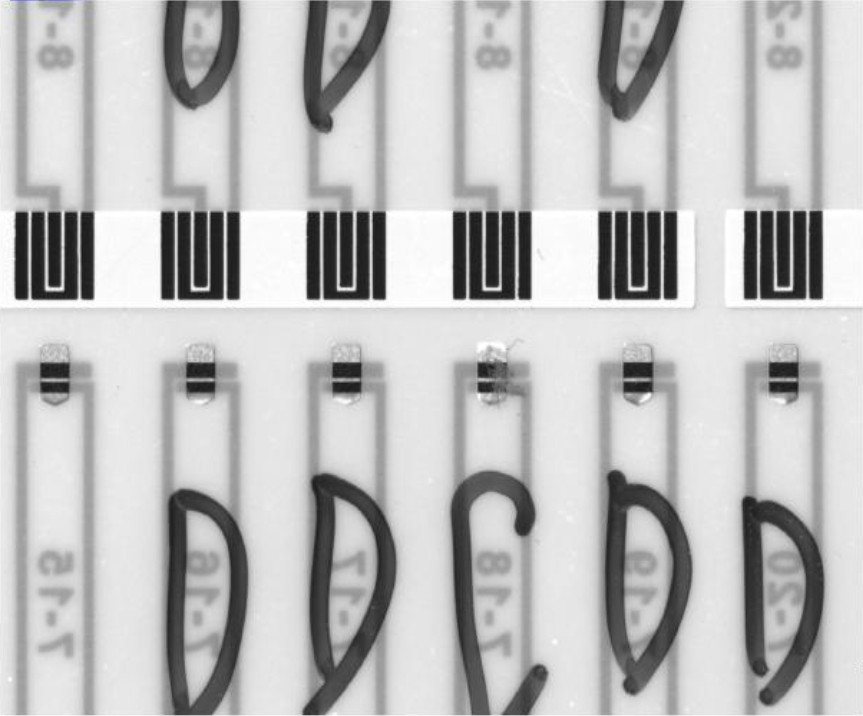

2, and blood sugar strips products with machine Visual detection production process in the bad products (electrode defects, and guide pass, and designated marks, siphon slot offset, enzyme whether full, CD cut whether accurate, Enterprise trademark whether clear, up to 15 items detection function) for urine try article products detection (filter paper whether offset, filter paper color whether normal,) detection, can achieved 24 hours no artificial participation Xia detection products, through network links can achieved entered to ERP software real-time view capacity, and Andoutput to the quality assurance Department to implement on-site monitorproduct quality and inspection shall be used to test each batch each testdata, as well as all of the photos taken by the CCD. Very ideal auxiliaryequipment manufacturing companies.

3 hardware and software standard for: Germany us industrial high speedcamera, Japan Pentax focus lens, which enable high-speed stability testing

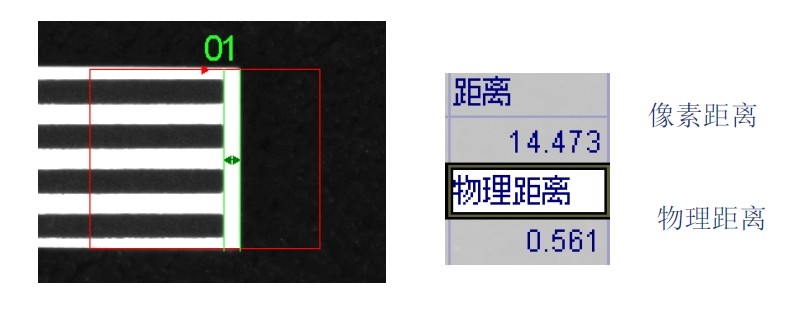

4, size measurement: blood glucose test strip detecting shape of whitespace and cutting precision, measurement accuracy up to +-0.03mm

Special products such as size requirements with 2 measuring instrument, upto 150 times magnification, high measurement accuracy up to +-0.001mm

5, customized for specific customer enhance remote communication, in orderto facilitate future maintenance and software upgrades.

6, the interface is simple and straightforward, and with the productiondatabase, and defective products database, edit the program with teachingmodel, do not repeatedly turn the interface settings item, logic of thehuman mind, gives a comfortable, relaxed working conditions

7, reserved I0 interface to customer convenience the device fitted to theautomation station as a production on the Assembly line.

Technical parameters:

Model

WM-601

Plane travel of table

100-460mm work products to determine the size of the table, as well ascoordinate ranges

IO interface

IO interfaces will provide 0V and 24V power supply to the input/output PNPand NPN signals.

Communication extension

Reserve link ERP system communications protocols, product production andnumber of defective links your production management system in real time.

Other extensions

CCD camera extension in the future if you need to upgrade multiple CCDdetection lens, to test different products at the same time, withoutchanging the original system.

CMM movement speed

15 m/minute maximum

Detection time

About 10-30 milliseconds to complete product testing

Visual control system program

United States NI

Vision algorithms and procedures

Their own research and development

PC operating systems

Genuine Microsoft WINDOWS operating system

Measurement accuracy

+-0.04mm

Mechanical dimensions

Device profiles according to the request variable

Machine weight

About 60KG

Consumption power

1.25 KVA

Using the power

AC220V/50、60HZ

Equipment constantly updated against change without prior notice.