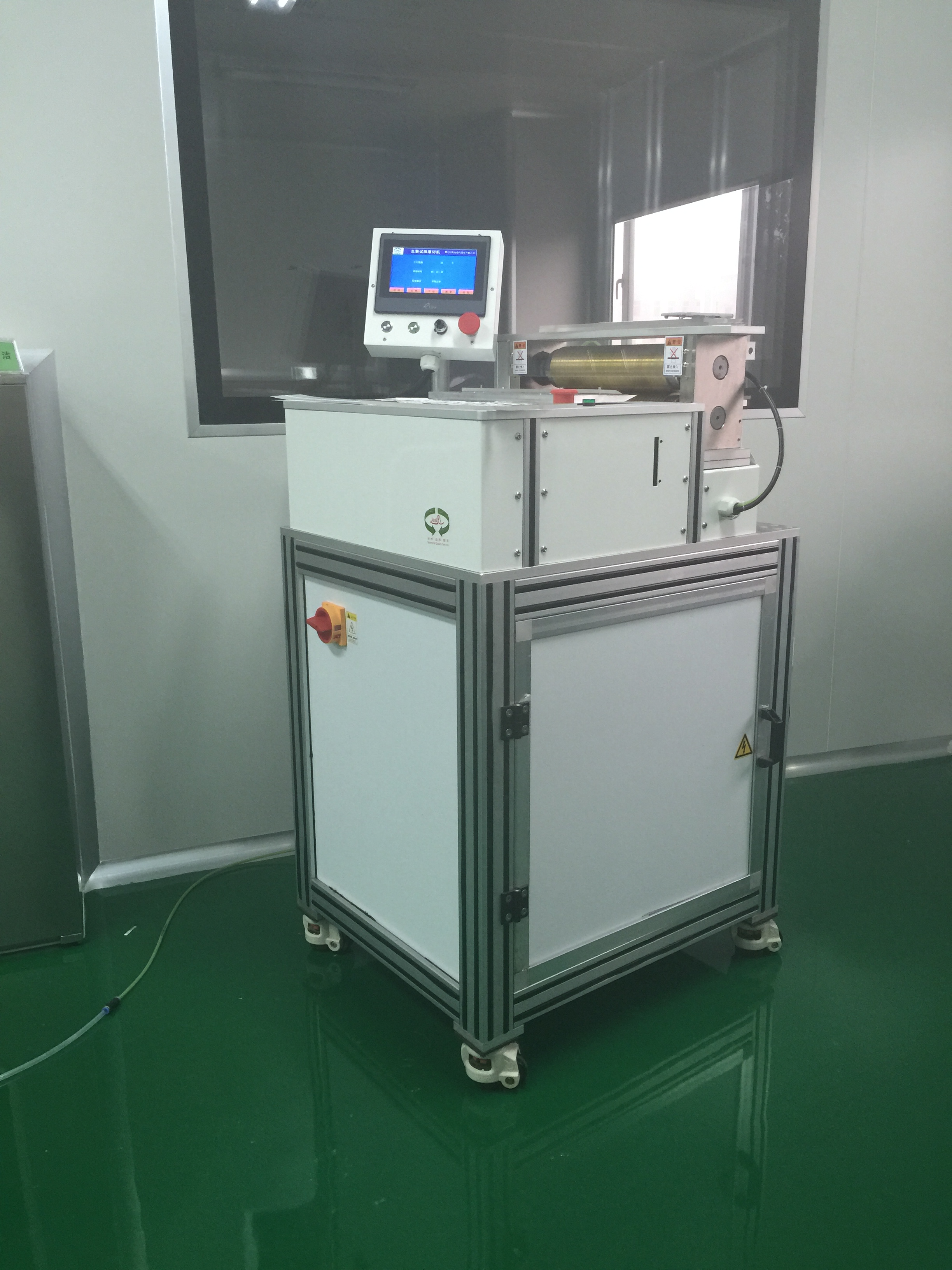

Automatic registration roll cutting machine for blood glucose test strip

Description:

1. This equipment is a high-precision and high-efficiency rolling cutting device developed for blood glucose test strip manufacturers.

2. Equipment is divided into: 1. with automatic induction specific identification, automatic correction, 2. manual edge alignment, 3. positioning hole positioning. 3 types of positioning methods. With fast speed, high efficiency and stable quality, it is a very ideal production equipment for production enterprises.

3. The test paper printed with specific marks and color blocks (such as electrodes or other lines) on the surface and digital optical fiber scanning for precise positioning.

4. For positioning of artificial edge, positioning hole positioning. No editing program is required for the type of device. Simple and fast operation

5, using D2 alloy blades imported from the United States or F2A high-speed alloy steel blades from Japan, has good wear resistance and durable. It can be estimated that the customer needs titanium treatment. Generally, it can be used for 2 to 3 years without grinding.

6. The equipment can be positioned as a separate station on the production line and cooperates with the production line for fully automatic production.

7. The device is easy to operate. Do not flip the interface setting items repeatedly. The manual optical alignment function does not need to edit the program. Logic conforms to human thinking, giving people a comfortable and relaxed working state

Technical Parameters

model

WM-220

Worktable stroke

100mm-320mm to determine the work surface according to the product size

Cutting accuracy

Optical fiber induction: line error + -0.1mm (length within 100mm)

Manual positioning type: line error + -0.1mm (length within 100mm)

There will be slight floating depending on the material

Rolling blade accuracy: + -0.005MM

Maximum slice width

5-8MM / width as required

Targeting

3 functions / contains

1 hole positioning

2 sideline positioning

3 fiber positioning

3 functions can be selected.

Rolling channel (number of pieces)

25-50 tablets (customized according to customer needs)

Applicable thickness

Within 0.85mm (PET material)

Cutting speed

220 rpm max. Speed adjustable

Program operation

Touch screen human-machine interface input

Mechanical Dimensions

600MM * 700MM * 1200MM (the size of the device will vary according to the layout)

Gas source

0.6Mpa (clean gas source)

Mechanical weight

About 85-180KG (depending on the size and weight of the device)

Power consumption

0.7KVA