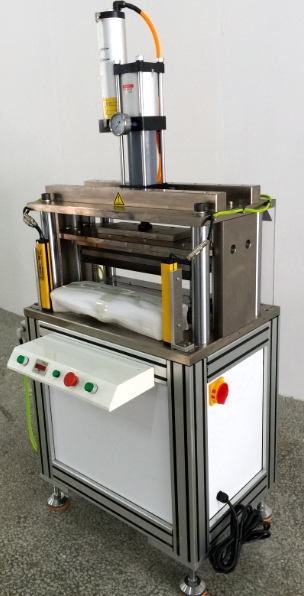

Dry chemical test paper substrate forming equipment

Description:

Equipment function: The equipment can be applied to the cutting equipment of the dry chemical test paper large-scale base material die cutting process. The operator places a single test paper substrate in the mold groove of the device, presses the device switch with both hands, and the device automatically punches out.

· After the blanking sheet is completed, the tail material is taken out by the operator.

The test paper circular shaped tail material is automatically dropped into the equipment recovery box. Simple and fast operation. Easy maintenance and other features

Device parameters;

model

WM-201

Control System

MCU control unit

Save memory

Built-in chip storage

Punching speed

Once every 6 seconds

Blanking standard efficiency

90 punches per minute for maximum sports

Mold wear rate

About 50,000 cuts

Mold replacement efficiency

Completed in about 10 minutes

Infrared safety sensor

10 ms response time

Mold material

SKD-11

Operation method

Foot switch / or dual switch button

Pressure driven

Pneumatic, driving hydraulic pressure. The stroke range of 5 tons pressure is 10MM

Mold stroke

100MM. The stroke range of 5 tons is 10MM

Program operation

No editing program

Mechanical Dimensions

According to product layout

Mechanical weight

About 120KG designed according to product layout requirements

Power consumption

0.2KVA

air pressure

5kgf / cm²

using electric

AC220V / 50, 60HZ